The production of cement is an energy intensive process. More than 100 kWh of electrical energy and around 4 GJ of thermal energy are required to produce one ton of cement.

This thermal energy is traditionally provided by coal, gas as well as oil and its products like pet-coke. To replace these fuels by alternatives is a goal of the lawmakers around the world due to different reasons:

On one side, the carbon footprint of the industry shall be reduced. Globally, cement production currently produces 7% of the man-made carbon emissions. Utilization of alternative fuels and raw materials is foreseen as one major contribution of cement industry in the global reduction of carbon emissions to counter the anthropogenic global warming.

Secondly, preservation of precious fossil resources is of governmental interest. For example, instead of being used as fuel in a clinker kiln, oil can be used as raw material for petrochemical industry having much higher economic value for a country.

The cement industry has to follow these legal requirements.

On the other side, utilization of alternative fuels and raw materials can have a positive impact on the economy of cement production. Traditionally, even more than 30 % of total production costs have been related to fuels. Depending on the legal regulations and the composition of the waste to be burnt, increasing the use of alternative fuels in the cement industry can decrease the production costs respectively source an additional income for the cement producer.

What is waste?

Wastes are unwanted or unusable materials. Waste is any substance which is discarded after primary use, or is worthless, defective and of no use. Typical waste classified as alternative fuel are, for example, waste tires, waste oil and solvents, industrial and domestic waste, plastic, textile, paper waste and waste wood.

A large variety in physical and chemical composition is presented in the waste. Meaning that preparation of an appropriate alternative fuel, in accordance with requirements of the clinker production, is a complex process and requires close quality control. Before starting co-processing waste in cement manufacturing, basic quality requirements must be considered.

What is pre-processing and co-processing?

Pre-processing in general is the preparation of waste to make it suitable for firing in cement kilns. Waste is converted from an unwanted discarded material to a useful resource, the so-called alternative fuel and raw materials.

Co-processing can be defined as usage of alternative fuel and raw materials in cement manufacturing process for the purpose of energy and/or resource recovery, resulting in reduced consumption of conventional fuels and/or raw materials through substitution. This enables substitution of primary fuels (oil, coal, petroleum coke, natural gas) and raw materials, recovering energy from the waste and recycling its mineral content.

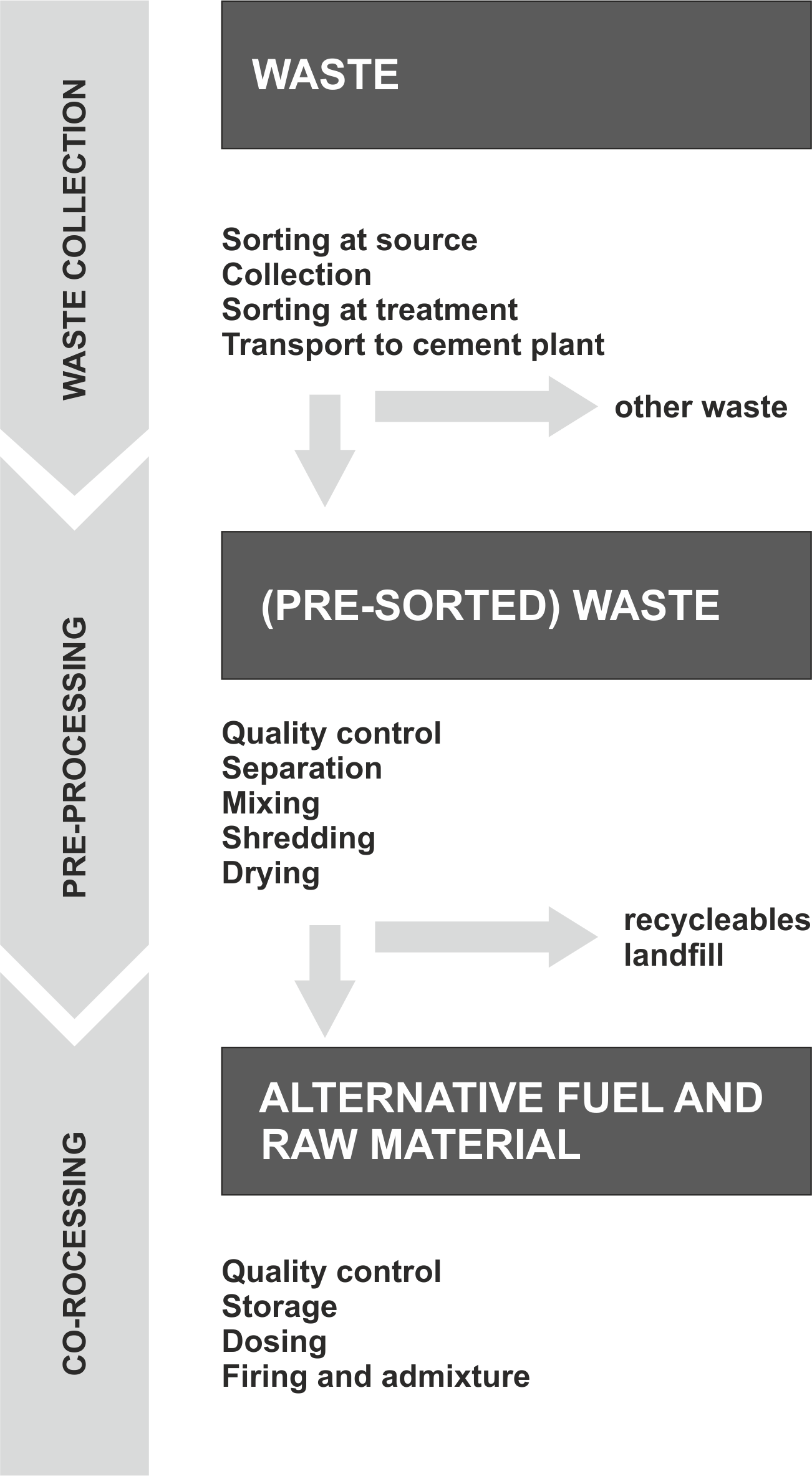

There is no standard procedure for utilization of waste in a cement plant. The process consists of mainly three important steps:

The waste collection

The waste has to be collected and might be already sorted at the source. This depends very much on the kind of waste, e.g. municipal waste differs dramatically from single-source industrial waste or tires. The sorting at the source or the sorting at the waste treatment plant differ for country to country. The co-processing project has to take this into account.

The pre-processing

The necessary treatment of waste before firing is summarized as pre-processing. This includes, next to quality control, separation, drying, mixing and shredding in various ways and combinations. Next to the production of the alternative fuel and raw materials, also recyclable materials like metals might be gained as well as non-combustible materials for landfill. The main product is the alternative fuel ready for being fired in the kiln or calciner.

The co-processing

The alternative fuel is stored in order to gain a continuous and homogeneous flow for firing. Co-processing includes, next to quality control of the fuel, the dosing and firing. Possible feeding points for alternative fuels are the kiln burner, the calciner burners or separate equipment at calciner or kiln inlet.

Due to the differences in temperature between different parts of the clinker production process, it is important that waste fuels and raw materials are introduced through an appropriate installation at the correct points in the process to ensure complete combustion or incorporation and to avoid unwanted emissions. For example, raw materials with volatile organic components may be introduced in the kiln at the main burner, in mid-kiln, in the riser duct, or at the pre-calciner. They should not be introduced with other raw materials, except where tests demonstrate that this will have no effect on gas emissions. Therefore, in most cases, a specific additional installation needs to be built to input these materials into the system.

Key benefits of waste co-processing:

- Reduce fossil fuels consumption

- Reduction in CO2 emission

- Fast return of investment

- Contribution to local waste management

- Lower energy costs

- Gaining of additional income

In order to develop and implement your co-processing project with the expected results, IBBL has developed six steps for implementation. Please see IBBL Service page describing these six steps.